Safeguarding Earth’s Tomorrow, Today.

Advancing climate-tech via low-carbon lithium ion battery recycling, producing sustainable battery metals & chemicals from used batteries.

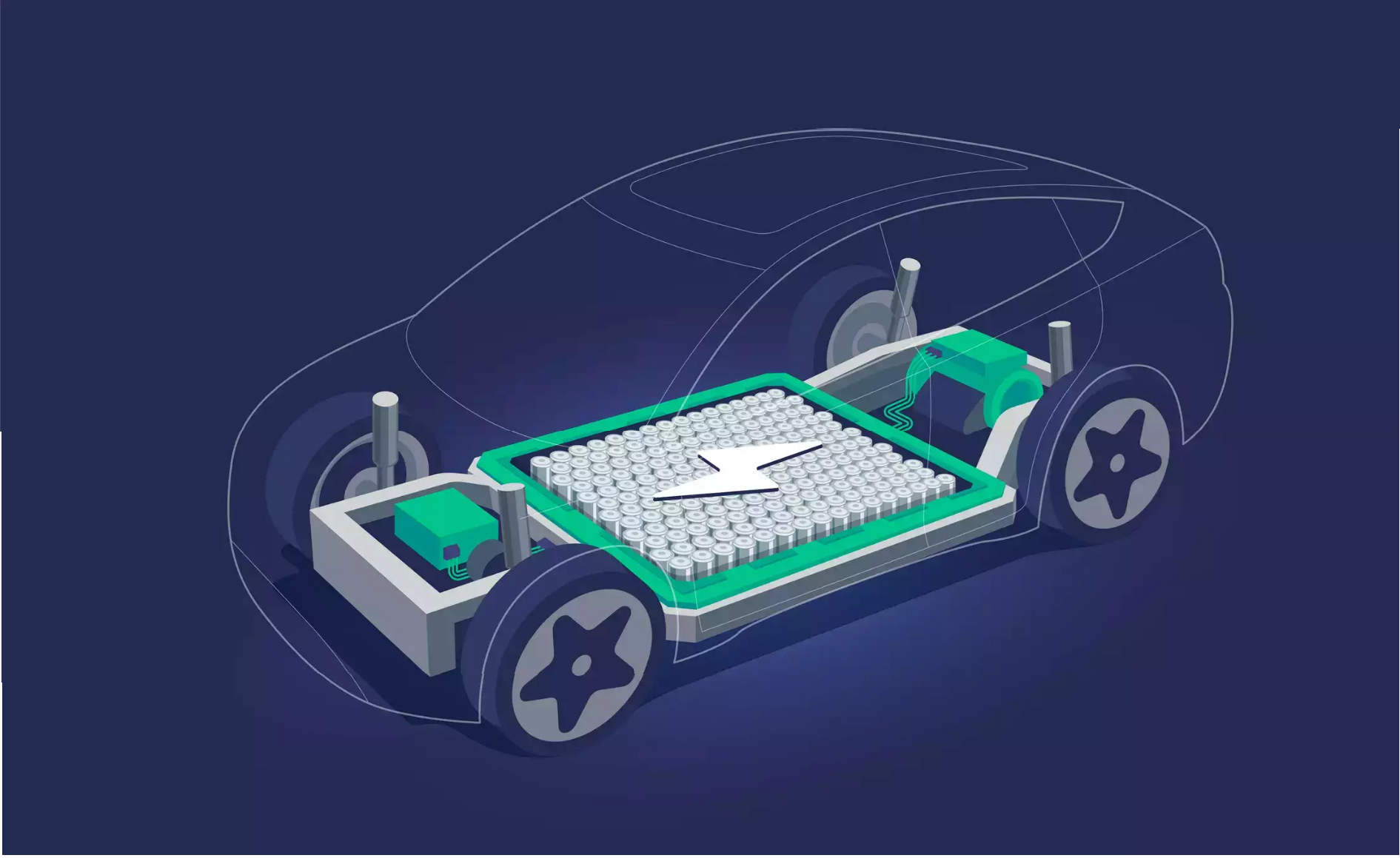

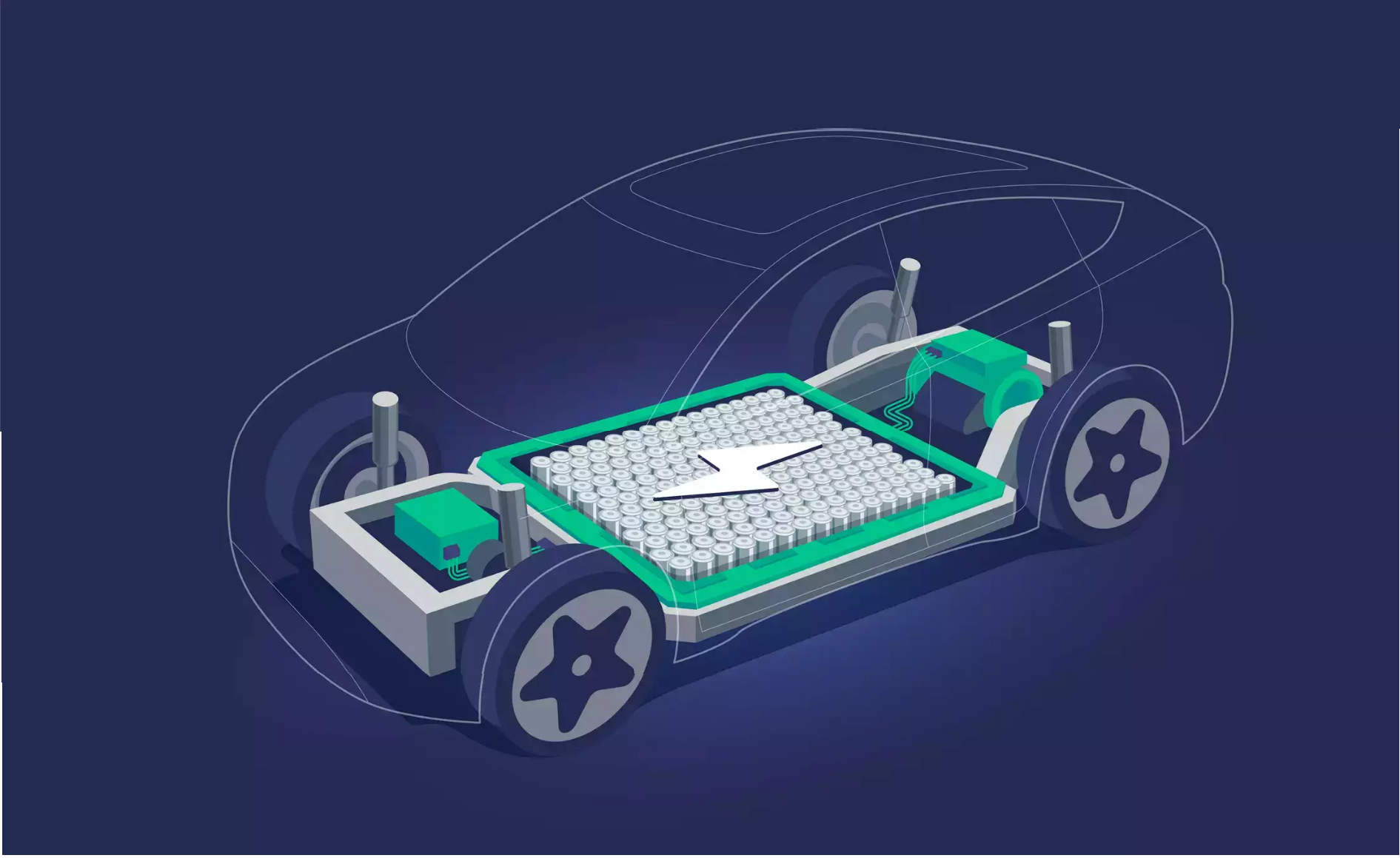

Rising temperatures, severe weather conditions, increasing droughts, floods, hurricanes, the list of dangers induced by climate change is alarming. The world is scrambling to shift away from fossil fuels, and towards clean energy powered by Lithium ion battery recycling.

In our quest to push the energy industry closer to net zero, we strive to be a key pillar of closed-loop Lithium ion battery recycling and repurposing.

We reduce dependency on mining for battery minerals by fostering a 100% circular supply chain with unparalleled transparency. At LOHUM, accelerating the shift towards a circular, responsible, and climate-conscious battery ecosystem is at the core of all decisions!

LOHUM: The largest producer of sustainable energy transition and battery raw materials through recycling, repurposing, and low carbon refining.

LOHUM: the largest producer of sustainable battery raw materials through recycling, repurposing, and low-carbon refining.

As a climate-tech company, we host single-point lithium ion battery recycling & reuse solutions to overcome industry-wide obstacles to sustainable energy storage.

We’re the charge behind environment-focused battery energy technology, and we’re building a zero-waste battery materials supply chain to power the entire industry.

The critical lithium ion battery raw materials we recover and recirculate to the market lower battery costs, reduce reliance on mining, and advance energy security for all.

As an OEM or Dealership, are you looking to recycle your used or scrap batteries?

Achieve your battery sustainability goals through our NEETM™ Lithium ion battery recycling and extraction technology.

Are you an OEM, or Financier looking to discover the residual value of your Lithium ion battery?

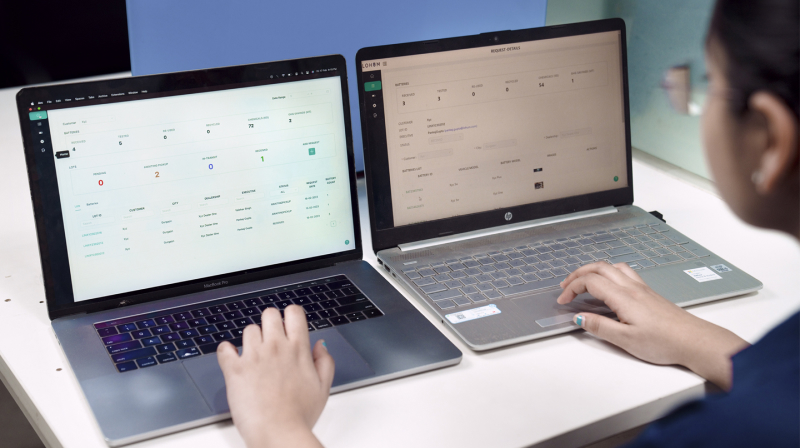

Access industry-leading salvage prices in real-time via the DETX™ index, and unlock optimal second life applications.

Are you a battery manufacturer looking to fulfill your Extended Producer Responsibility (EPR)?

Ace your EPR targets with our traceability and EPR portal that generates BWMR-compliant lithium ion battery recycling certificates.

For homes, offices, and industry powered by repurposed 2nd life Li-ion batteries.

Li-ion 2-wheeler and 3-wheeler applications for tough operating environments.

High-purity battery raw materials ready for use in the production of Cathode Active Materials (Li, CO, Ni, Mn) and Anode (Graphite), recovered via our NEETM™ Lithium ion battery recycling technology.

Battery materials can be recycled and reused endlessly. What is currently treated as waste can be reclaimed with our patented NEETM™ process, and recirculated infinitely.

Kgs CO2e saved per KWh of Lithium ion battery recycling capacity vs mining.

Kgs CO2e saved per KWh of reused battery capacity vs mining.

Less water consumed per ton of LIBs recycled. Mining consumes 500,000 liters!

Lithium ion battery recycling industry jobs created by 2026

The world’s transition to battery power presents various environmental, humanitarian, and geopolitical challenges.

At LOHUM, we’ve set out to holistically address challenges obstructing the battery energy revolution, paving the way for the widespread adoption of circular-economy LIB technologies.

Battery materials critical to meet rising energy storage needs require labor, energy, and carbon-intensive refining, rendering massive environmental and humanitarian costs. We directly impact the mining needs of the industry by recirculating reclaimed critical metals back into the supply chain via Lithium ion battery recycling.

Millions of used lithium-ion batteries enter the waste stream, of which the majority currently end up in landfills or worse, toxifying the surrounding land, water, and potentially air if burnt. We make it much simpler and cost effective to safely recycle discarded lithium ion batteries and scrap, with convenient logistics that span Asia, North America and Europe.

Even as newer economies strive to upscale production and tackle battery waste, the core issue remains the concentration of natural reserves and refining capacities in a few resource-rich nations, lending geo-economic advantage to a select few. We help develop self-reliance in energy storage via Lithium ion battery recycling to prove that domestic battery manufacturing can be fostered via a robust circular-economy of raw materials.

At the end of its life, a typical Lithium-ion Battery changes many hands, and jumps through logistics hoops that shouldn’t be there. We are here to change that. Pick-up, processing, and drop-off with full traceability and maximum safety is our promise that starts at your doorstep. We work closely with a reliable network of global logistics partners to support you in transporting your batteries safely to our facilities for Lithium ion battery recycling.

The industry is currently opaque, hiding processes that are anything but environmentally and human friendly. Once a battery goes out of the production line, it is usually unclear what happens to it. It is not just the mining activities which are suspect, but processes used in refining, production, as well as Lithium ion battery recycling, leave much to be desired. We address this by championing an end-to-end traceability system for full visibility on every gram of raw material that we buy from and sell to you.

Our patented NEETM™ Lithium ion battery recycling process and advanced cell analysis techniques with 95% yield are our most directly sustainable & carbon-reducing contribution to support the future of our planet via LIB recycling and reuse.

Learn More

LOHUM strives to express our commitment to Environment, Social, and Governance by adhering to and surpassing rigorous global standards and ethics across all levels of our organization.

Learn More

Critical battery raw materials are finite on Earth, yet are a sizable percentage of e-waste that escapes reuse or recycling. We’re committed to making their recirculation the industry-norm via high-yield Lithium ion battery recycling. We make it easy for customers by providing end-to-end traceability and reverse logistics services.

Learn More

We commit to hearing out and interacting with our people, suppliers, customers and other stakeholders for their invaluable feedback and to understand their Lithium ion battery recycling and reuse needs.

Learn More

We’re always on the lookout for people with the passion, drive, and determination to make the world a better place!

LOHUM is India’s largest producer of sustainable energy transition materials, and the only integrated battery material recycling, reuse, and low-carbon refining company in the world. We are also a green ecosystem employer that revels in building careers that empower ambition, enrich lives, and excite passion! At LOHUM, we build experiences that help uplift both individuals and communities.

Our work environment radiates equity, inclusion, and diversity, and every day offers endless possibilities for growth and learning.

October 26, 2023Lohum

September 14, 2023Lohum

Mint

The partnership will allow both companies to deepen their recycling expertise and support the advancement of a circular economy by supplying raw materials back into the battery supply chain.

Bloomberg

Mercedes-Benz Energy and LOHUM are pleased to announce a strategic partnership through a multi-year supply contract agreement for second-life batteries.

PTI

Recognised for making India a viable alternative to International players in the battery raw materials space and helping India potentially capture at least 10% share of the global battery raw materials market

Have Lithium ion battery recycling, reuse, or EPR requirements?

1800 572 8822

Email : enquiry@lohum.com

G98, Site, 5, Kasna, Block A, Surajpur Site V, Greater Noida, Uttar Pradesh 201306

LOHUM Cleantech Private Limited, Plot No. D-7 & 8, Site 5th, Kasna Industrial Area, Greater Noida, Gautam Budh Nagar, Uttar Pradesh – 201308

LOHUM Cleantech Private Limited, Plot No. O-17, Site 5th, Kasna Industrial Area, Greater Noida, Gautam Budh Nagar, Uttar Pradesh – 201308