24 Hrs

For Tier 1 Cities48 Hrs

For Tier 2 Cities

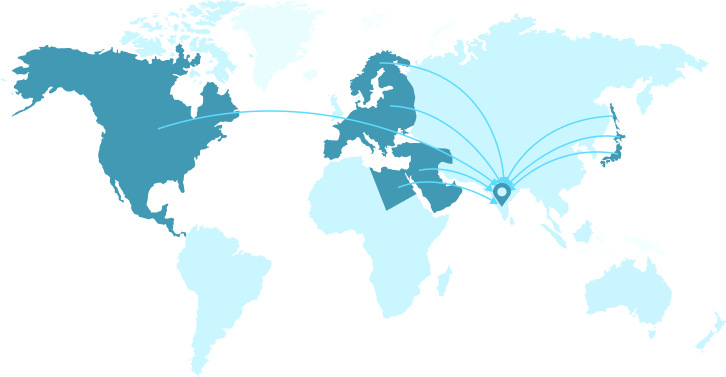

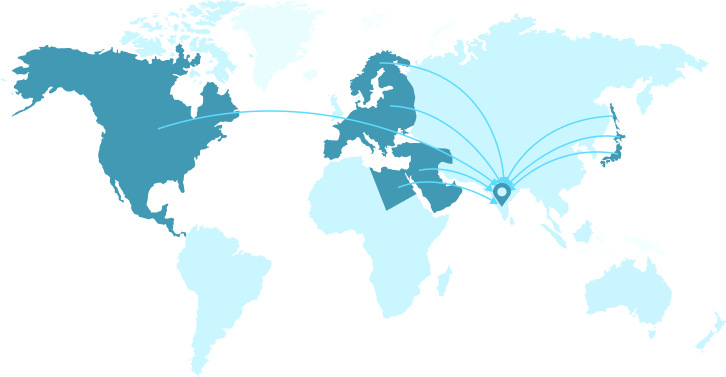

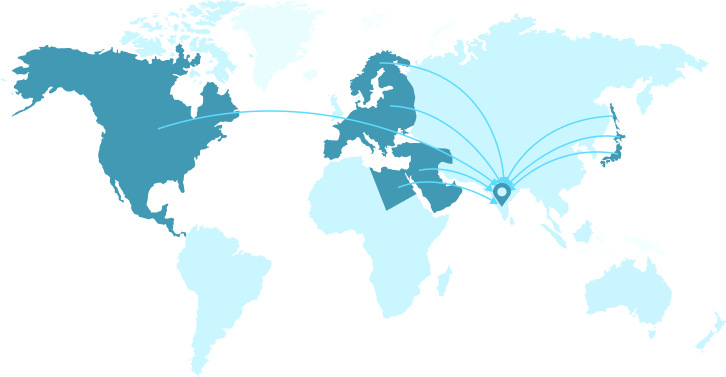

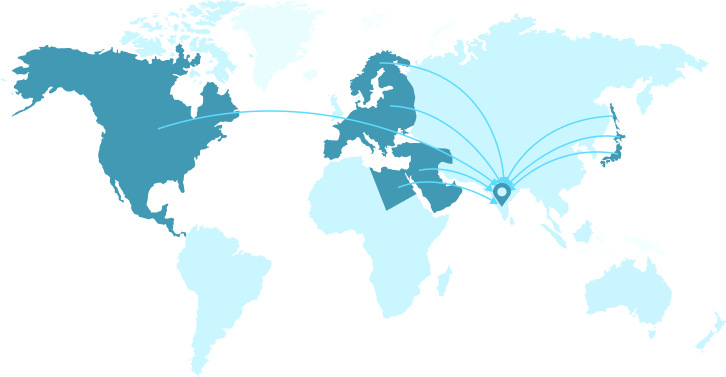

Distance is no bar as we work closely with a reliable network of global logistics partners to support you in transporting your batteries safely to our facilities.

Leverage technology that yields more, and makes battery materials 100% sustainable.

We recover critical Li-ion raw materials via our pioneering Metelec™ recycling technology to recirculate them into the battery ecosystem.

Our low-CO2e battery recycling and repurposing process ensures high-yield recycling of Li-ion batteries, and builds an environmentally sustainable supply of raw materials.

We believe that wherever possible, 2nd life combined with recycling offers the best solution for sustainability and value creation over the long term.

We recover critical Li-ion raw materials via our pioneering NEETM™ recycling technology to recirculate them into the battery ecosystem.

Our low-CO2e battery recycling and repurposing process ensures high-yield recycling of Li-ion batteries, and builds an environmentally sustainable supply of raw materials.

We believe that wherever possible, 2nd life combined with recycling offers the best solution for sustainability and value creation over the long term.

Our reverse logistics network spans all of India and beyond, and our responsibility starts at your doorstep. Via proprietary transport technologies we ensure quick & safe transit of your batteries to us. All batteries are bar coded and made traceable throughout the battery recycling & reuse process.

Wherever you may be situated in India, we’ll pick up your batteries within:

Distance is no bar as we work closely with a reliable network of global logistics partners to support you in transporting your batteries safely to our facilities.

Through our DETX™ battery price index, we give you ‘future’ purchase prices to help you get into buyback agreements with your customers.

The index reflects the live movement of material prices based on global demand and supply, and insulates energy transition ecosystem stakeholders against price fluctuation.

As the only company to house such an extensive battery price index driven by data from battery recycling and reuse, we unlock numerous advantages for you:

Through our end-to-end EPR and traceability portal, we enable full visibility on the status of your batteries and help you meet all your battery recycling compliance requirements transparently.

Our software gives you real-time access to:

All the materials present in a battery at the beginning of its life are also present at the end of it.

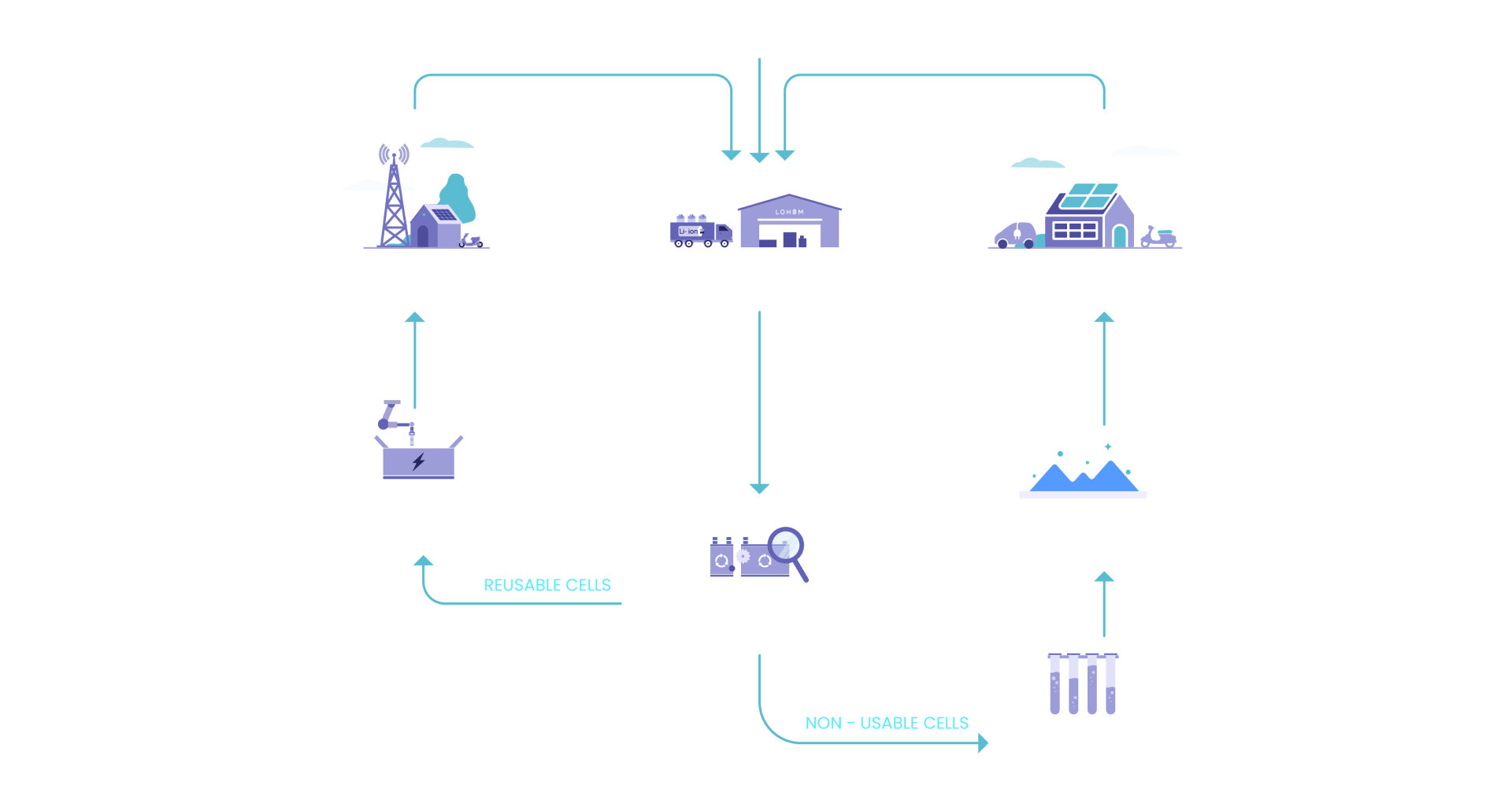

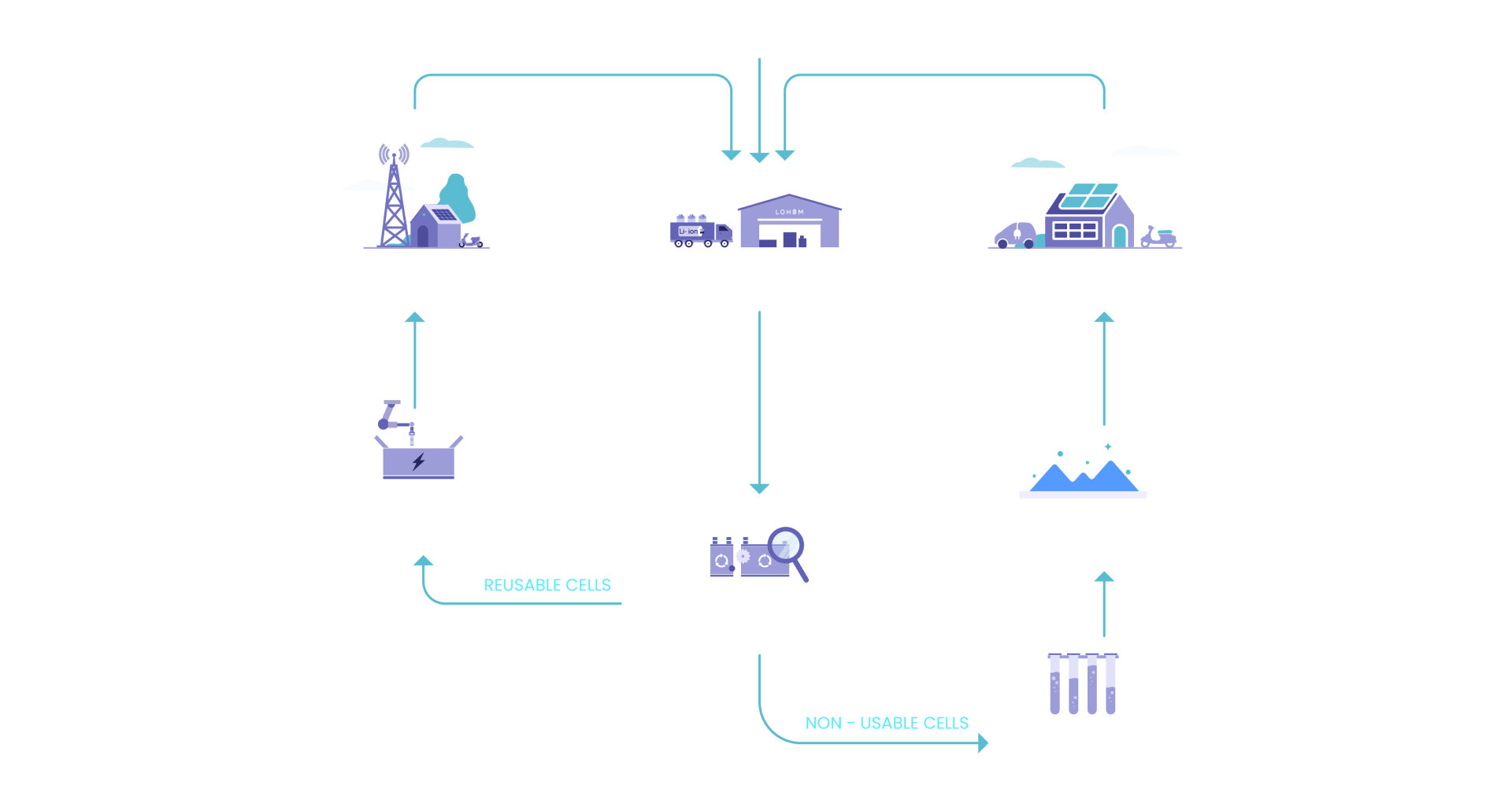

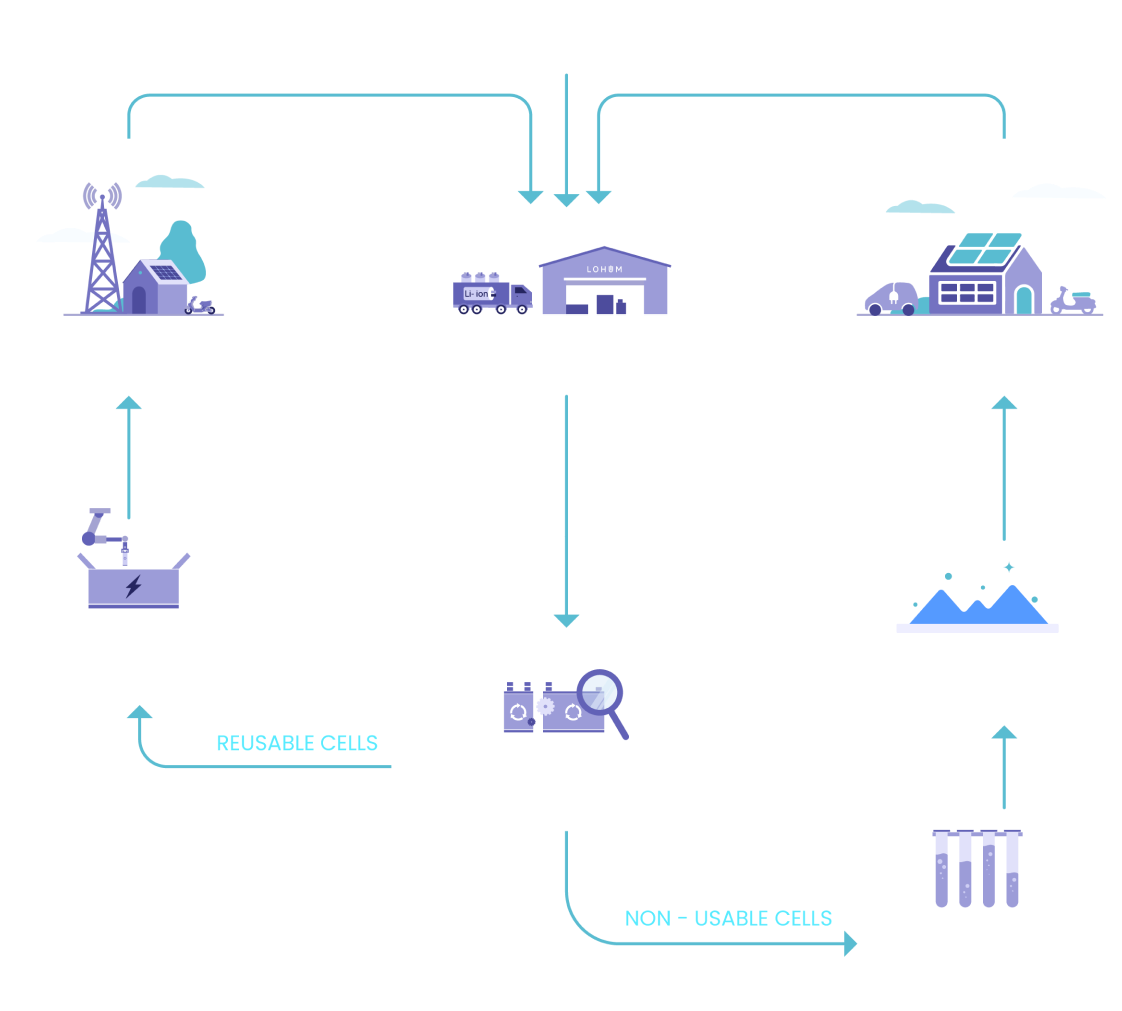

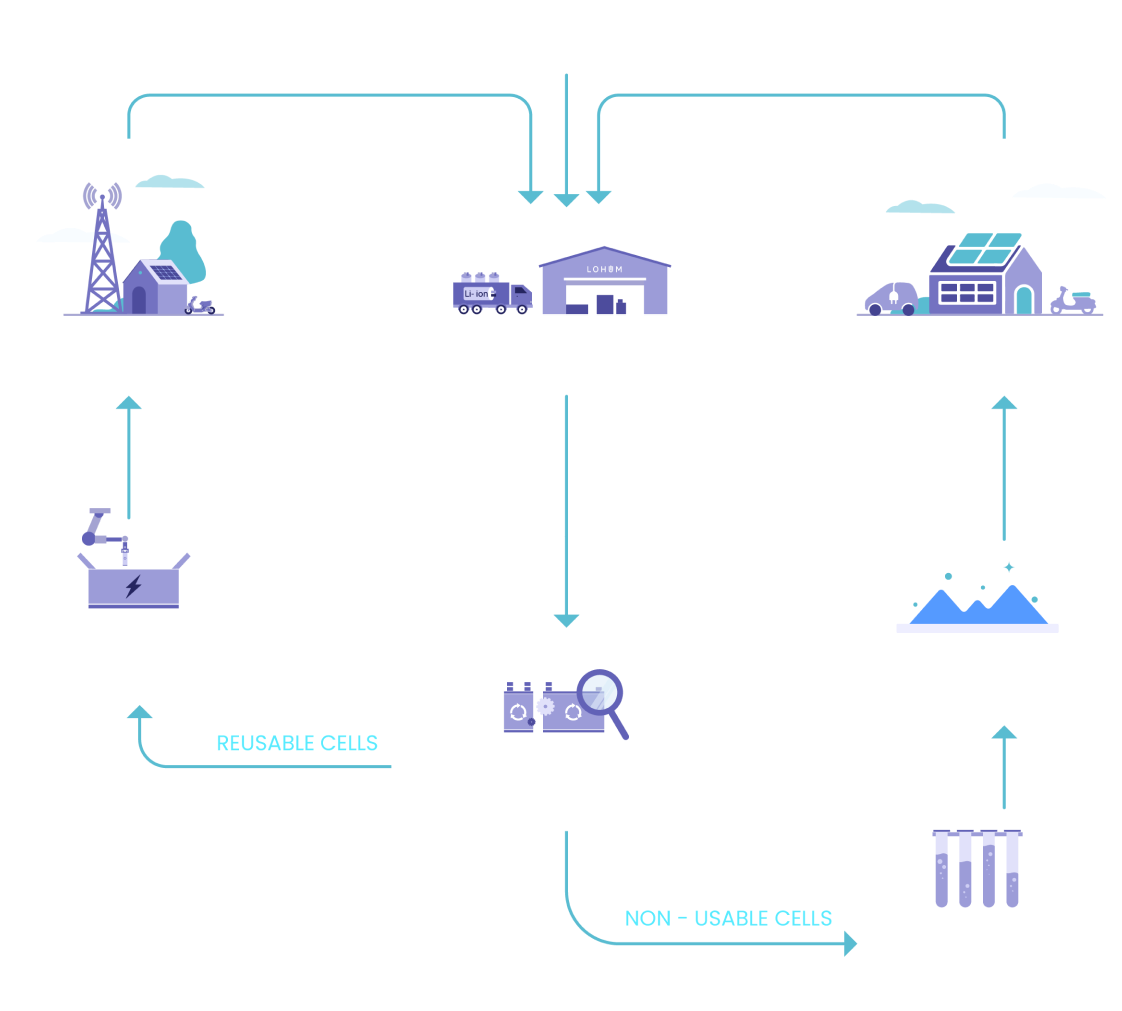

We rapidly determine if your battery cells can be reused or need to be recycled via state of health testing and remaining useful life analysis. We recycle all kinds of Li-ion batteries, irrespective of their cell chemistry and form.

Here’s how we close the loop and make Li-ion raw materials last forever.

There are various companies engaged in Lithium ion battery recycling and carrying out material extraction via different technologies.

However, our patented NEETM™ Lithium ion battery recycling and extraction technology has been perfected to yield top quality materials, produce zero waste and be highly scalable. All while simultaneously incurring significantly lower financial and environmental expenses.

01. Our Cobalt & Nickel extraction process is agnostic to the percentage of contained cobalt & contained nickel.

02. We host direct recycling of LFP at industrial scale via a proprietary cathode & anode separation process.

03. Extraction of Lithium Carbonate via proprietary membrane separation technology.

04. Complete electrolyte recovery via proprietary absorption & release techniques.

We also specialize in reviving end-of-life EV batteries and maximizing their potential before battery recycling, through integrated cell reuse capabilities. Through repurposing we maximize value from cells with remaining useful life.

RUL Prediction

Most research on Remaining Useful Life (RUL) prediction is theoretical and limited to specific kinds of batteries, usually the OEM’s own batteries, or batteries in controlled operating conditions (laboratory).

01. All our processes are agnostic to battery form factor, chemistry, and cell architecture.

02. We provide accurate estimates in both data-constrained and data-rich scenarios.

03. Fast and real-time computational models for easier decision making.

04. Comprehensive electrical, mechanical, electrochemical evaluation of used batteries through a proprietary testing protocol.

Have Lithium-ion battery recycling, reuse, or EPR requirements?

1800 572 8822

Email : enquiry@lohum.com

G98, Site, 5, Kasna, Block A, Surajpur Site V, Greater Noida, Uttar Pradesh 201306

LOHUM Cleantech Private Limited, Plot No. D-7 & 8, Site 5th, Kasna Industrial Area, Greater Noida, Gautam Budh Nagar, Uttar Pradesh – 201308

LOHUM Cleantech Private Limited, Plot No. O-17, Site 5th, Kasna Industrial Area, Greater Noida, Gautam Budh Nagar, Uttar Pradesh – 201308